The EGS control always works in combination with one or more TecJet controls. In general, the EGS calculates the desired gas flow from the different engine and gas parameters. This gas flow is transmitted through a CAN link to the TecJet control(s). The TecJet control ensures that proper gas flow is maintained, regardless of gas pressure and temperature.

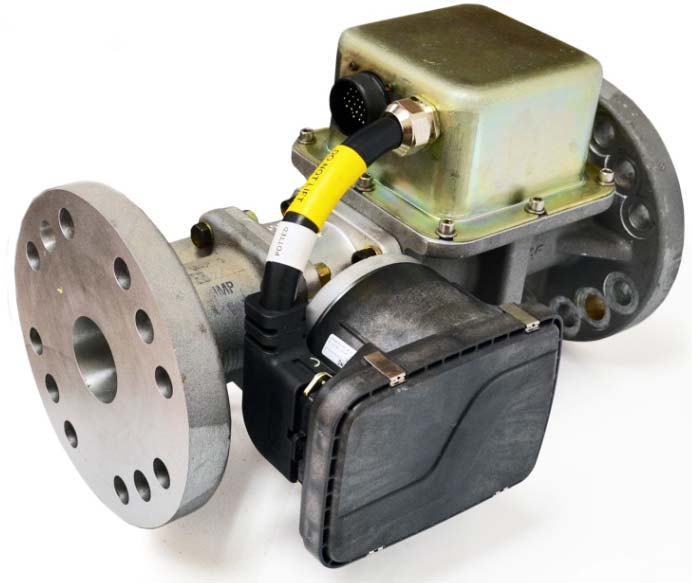

The TecJet is an electronic gas metering valve for singlepoint injection. It has integrated sensors and electronics, which provide the correct gas flow under all specified conditions. In general, a separate engine control system, like the EGS-02 control, calculates the desired gas flow from the different engine and gas parameters. This desired gas flow is transmitted through a CAN link to the TecJet valve(s). The TecJet valve ensures that the desired gas flow is attained, automatically compensating for changes in gas pressure and gas temperature.

The microcomputer inside the TecJet valve converts the desired gas flow signal and gas parameter information into a valve position (which corresponds to the desired gas flow), depending on gas inlet pressure, gas temperature, and the pressure difference across the valve.

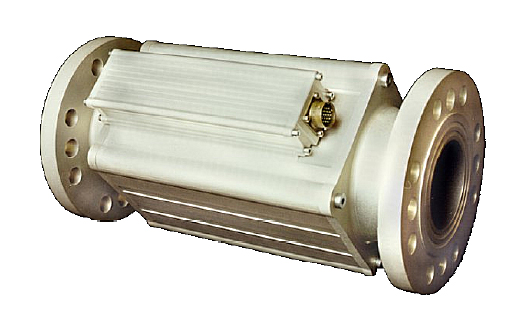

The TecJet 52 Gen II is fully backward compatible with TecJet 50 Plus and TecJet 52 valves. Its improved dynamic response and repeatability over these valves make transitioning to the Gen II a logical decision. Flow testing ensures that the engine does not have to be recalibrated when previous model TecJets are replaced.

Higher Range of Flow Capabilities

• TecJet 52 turndown ratio is 65:1, Gen II is 110:1

• This allows the TecJet to be used in a larger flow range, resulting in a wider range of applications.

Lower Closed Flow Leak

• Equivalent to 20% area reduction from 0.027 in 2 to 0.0215 in2

• This will allow for better startup and low-load control – especially at altitude.

Better Environmental Sealing

• TecJet 52 is not sealed to the environment. Gen II is NEMA 4.

• Gen II passes power washing without water ingress.

More Robust to Specialty Gasses

• TecJet 52 has unsealed bearings. Gen II has bearings sealed with gas resistant seals and grease.

• This will improve the product life in specialty gasses.

Lower Weight

• TecJet 52 weighs approx. 18 kg. Gen II weighs approx. 14 kg.

• This eases the installation process and reduces the energy transmitted to the TecJet valve during vibration.